Polypropylene

Polypropylene molding of plastic components: an efficient technique for durable products

Polypropylene molding is a key technique for producing lightweight, durable and highly functional plastic components. Thanks to its physical and chemical properties, polypropylene (PP) is one of the most widely used thermoplastic materials in the manufacturing industry. Its versatility makes it ideal for numerous sectors, including orthopedics, air treatment, water treatment, infrastructure and the electrical industry.

Specialized companies like Expyou use advanced molding technologies to transform polypropylene into high-precision components, ensuring quality, production efficiency and sustainability.

Characteristics of polypropylene in injection molding

Polypropylene is valued for its high mechanical strength, chemical stability and ease of processing. Depending on the application, different types of PP can be used:

- Homopolymer polypropylene (PP-H) – Offers superior rigidity and strength, ideal for industrial and technical applications.

- Copolymer polypropylene (PP-C) – Provides greater flexibility and impact resistance, perfect for components exposed to mechanical stress.

- Reinforced polypropylene (filled with fibers or additives) – Optimized for specific performance requirements, such as improved heat resistance or self-extinguishing properties.

Thanks to its chemical structure, polypropylene ensures excellent electrical insulation, abrasion resistance and high tolerance to chemical agents, making it suitable for a wide range of industrial applications.

How does polypropylene molding work?

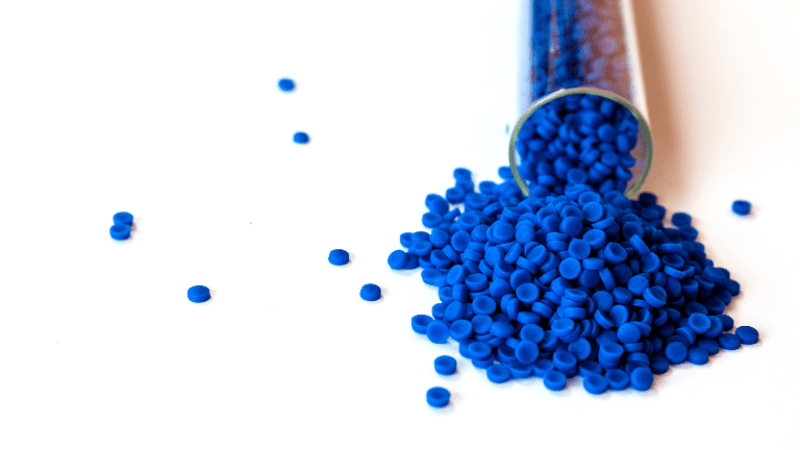

Injection molding is the most widely used technology to transform polypropylene into custom plastic components. The process begins with melting PP granules, which are injected under high pressure into a metal mold. After cooling and solidification, the part is ejected and, if necessary, undergoes finishing or assembly processes.

The use of advanced machinery and computer-controlled systems ensures precision, repeatability and a significant reduction in waste, optimizing the entire production cycle.

Key advantages

Polypropylene is one of the most popular materials in the industry thanks to its numerous benefits:

- High chemical and mechanical resistance – PP withstands aggressive chemicals, weathering and mechanical stress without degrading over time.

- Lightweight and flexible – Its low density allows the production of strong yet lightweight components, reducing transport costs and simplifying assembly.

- Cost-effective and recyclable – Polypropylene is inexpensive to process and fully recyclable, reducing the environmental impact of industrial production.

- Excellent insulating properties – PP has high electrical resistance, making it ideal for electrical and automation applications.

Why choose Expyou for polypropylene molding?

Choosing Expyou means relying on an experienced partner equipped with cutting-edge technologies for polypropylene molding. Our company offers:

- An advanced machinery fleet, with high-precision presses for complex parts.

- Rigorous quality control, ensuring components meet required standards.

- Certified materials, with tailor-made solutions for every industrial application.

- A sustainable approach, with optimized processes to minimize waste and environmental impact.

If you’re looking for a reliable partner for polypropylene component production, contact Expyou for a personalized consultation and discover how to optimize your manufacturing process with high-quality injection-molded plastic components.

Do you have any requests for us?

Fill out the form and we’ll be happy to get back to you as soon as possible.

Learn more about Netfix®,

the only certified orange construction net: fast and reliable protection for roadworks.